Electric wire has been a fundamental component in the development of electrical systems, playing a crucial role in the modern world’s infrastructure. Over the years, advancements in materials and technology have significantly enhanced the capabilities and applications of electric wire. This article explores the evolution of electric wire, from its rudimentary beginnings to the sophisticated materials used today.

Early Developments in Electric Wire

The inception of electric wire dates back to the 19th century, when the need for efficient electrical transmission became apparent. Early electric wires were primarily composed of simple conductors such as copper and iron. These basic materials were chosen for their conductivity, but they presented several limitations, including susceptibility to corrosion and inadequate insulation.

The first significant advancement came with the introduction of insulated electric wires. In the late 1800s, rubber and gutta-percha (a type of natural latex) were used as insulating materials. This development was pivotal in protecting the conductor and ensuring safety in electrical installations. However, the insulation materials of this era were still relatively bulky and prone to degradation over time.

The Advent of Modern Insulation Materials

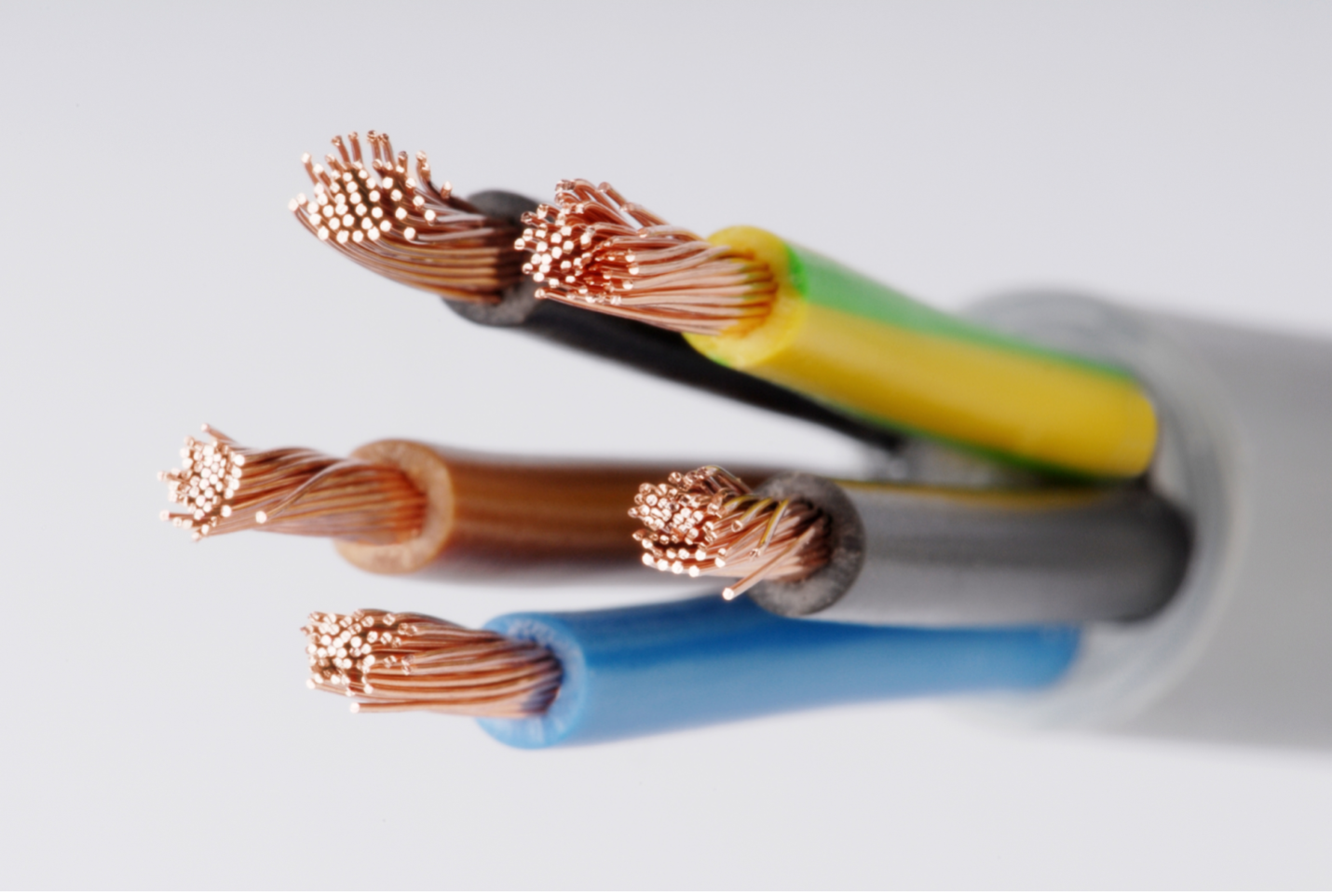

The 20th century saw a revolution in the development of electric wire, driven by the need for more durable and efficient solutions. The introduction of plastic polymers marked a significant shift from traditional insulation materials. Polyvinyl chloride (PVC) and polyethylene became the new standards for insulating electric wires due to their superior properties, including resistance to moisture, chemicals, and mechanical wear.

These modern insulation materials allowed for more compact and flexible wire designs, enhancing the ease of installation and reducing the space required for wiring systems. Additionally, the improved insulation properties contributed to increased safety by minimizing the risk of electrical shorts and fires.

Advances in Conductive Materials

While insulation materials saw considerable improvements, the conductive materials used in electric wires also underwent significant evolution. Copper remained the dominant choice for conductors due to its excellent electrical conductivity. However, advancements in alloy technology led to the development of new conductive materials with enhanced properties.

Aluminum emerged as a viable alternative to copper, especially for high-voltage transmission lines. Although it has lower conductivity compared to copper, aluminum’s lighter weight and lower cost make it a practical choice for certain applications. Additionally, advancements in aluminum alloys, such as ACSR (Aluminum Conductor Steel Reinforced), have further improved its performance and reliability.

The Emergence of High-Temperature and Specialized Wires

As electrical systems became more complex and demanding, there was a growing need for electric wires capable of withstanding extreme conditions. This led to the development of high-temperature wires designed for use in environments with elevated temperatures, such as industrial processes and aerospace applications.

Materials like silicone rubber and fluoropolymers, including Teflon, were introduced to address these needs. These specialized insulation materials offer exceptional thermal resistance and maintain their performance even at high temperatures. Such advancements have enabled the safe and reliable operation of electrical systems in challenging environments.

The Role of Smart and Flexible Wires

In recent years, the focus has shifted towards creating electric wires that can accommodate the evolving needs of modern technology. The advent of smart wires, embedded with sensors and communication capabilities, represents a significant innovation in the field. These wires are capable of monitoring electrical systems in real-time, detecting faults, and providing data for predictive maintenance.

Furthermore, the development of flexible and lightweight wires has facilitated innovations in various industries, including electronics and automotive. Flexible wires, often made from advanced materials like conductive polymers or nano-composites, are crucial for applications requiring intricate wiring and compact designs.

Environmental Considerations and Sustainability

As the demand for electric wire continues to grow, so does the emphasis on environmental sustainability. The production and disposal of electric wires have significant environmental impacts, prompting the industry to explore eco-friendly alternatives. Efforts are underway to develop recyclable materials and reduce the environmental footprint of wire manufacturing.

The recycling of copper and aluminum from old wires is a notable practice that helps mitigate resource depletion and reduce waste. Additionally, research into biodegradable insulation materials and energy-efficient manufacturing processes is ongoing to promote sustainability in the industry.

Conclusion

The evolution of electric wire has been marked by continuous advancements in both conductive and insulating materials. From the early days of simple conductors and rudimentary insulation to the sophisticated technologies of today, the development of electric wire has played a crucial role in the advancement of electrical systems and technology. As we move forward, ongoing innovations and a focus on sustainability will likely shape the future of electric wire, ensuring it continues to meet the demands of an ever-evolving world.