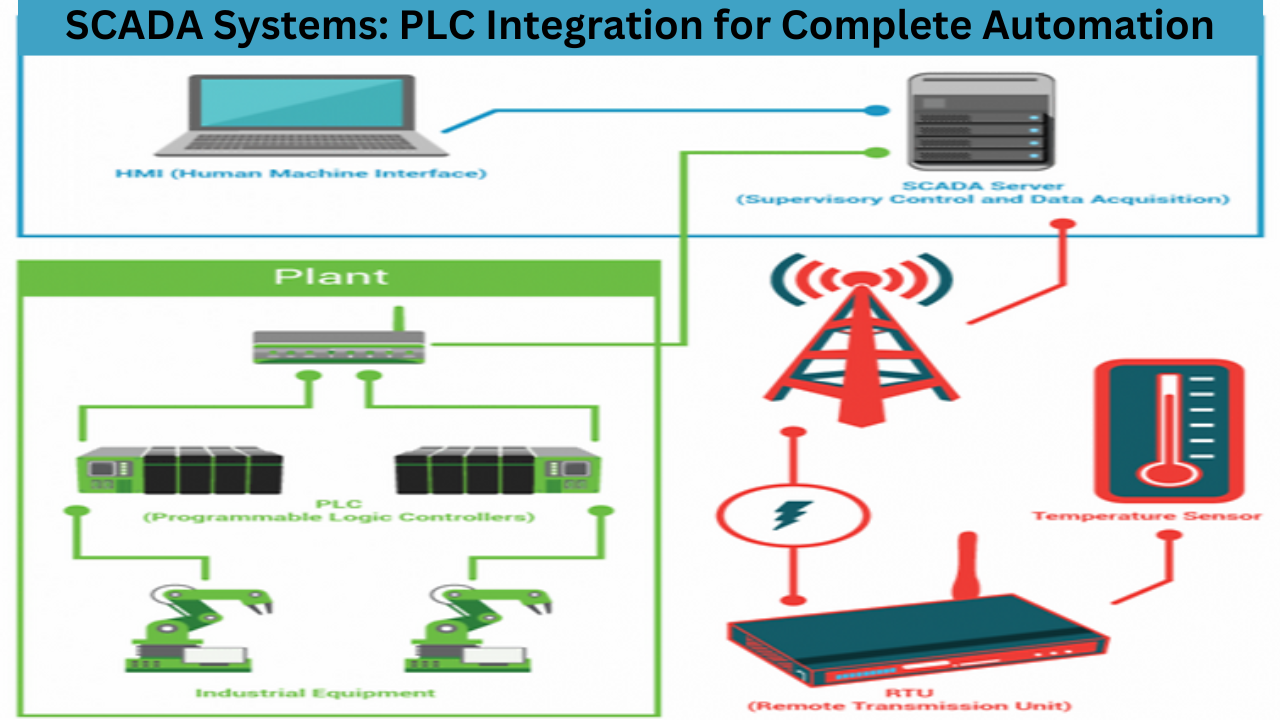

CADA (Supervisory Control and Data Acquisition) systems used in industrial automation to monitor and control a variety of systems, pieces of equipment, and processes. PLCs (Programmable Logic Controllers) frequently used in tandem with SCADA systems to provide real-time control and data collection for industrial operations. Integrating SCADA and PLCs can fully address industrial automation.

which has benefits such as increased productivity, reduced downtime, and improved safety.

Various SCADA and PLC integration techniques, best practices for design and security considerations, so case studies highlighting the benefits of integration in industrial applications also included.

We will discuss the benefits of combining SCADA and PLCs and provide an overview of both systems.

Overview of SCADA and PLC Integration

SCADA and PLCs two technologies that are frequently used in industrial automation.

SCADA systems used to monitor and control industrial processes in real-time .

while PLCs used to control a variety of equipment and processes.

A complete industrial automation solution can be provided using the two technologies in combination.

SCADA and PLCs work together to enable real-time monitoring and control of industrial processes, which boosts output and reduces downtime.

PLCs have the ability to send real-time data to a SCADA system for analysis and monitoring, and SCADA systems have the ability to visualize the industrial processes they are in control of it.

There are many ways to integrate SCADA and PLCs, including direct communication, OPC UA, Modbus TCP/IP, Ethernet/IP, and MQTT.

Advantages of combining SCADA and PLCs

-

Real-Time Monitoring and Control:

SCADA systems can enable real-time monitoring and control of industrial processes, and PLCs can control a variety of equipment and processes.

The combination of SCADA and PLCs enables real-time monitoring and control of industrial processes, enabling prompt responses to any process changes.

-

Increased Efficiency:

With providing real-time data and monitoring of industrial processes, SCADA and PLC integration can aid in improving efficiency. With the help of this information, process bottlenecks and inefficiencies can be quickly located and fixed.

PLC Architecture and Components

A frequent computer-base control system in industrial automation, the PLC (Programmable Logic Controller) is use to manage a variety of machines and processes.

The three essential components of a PLC system are input/output (I/O) modules, a central processing unit (CPU), and programming software.

Check :- Allen Bradley 1766-L32BWAA MicroLogix 1400 PLC

Input/Output (I/O) Modules

The PLC system’s sensors and actuators connected using I/O modules. These modules transform sensor and actuator signals into digital signals the CPU can understand. I/O modules, which can connect to different kinds of sensors and actuators like switches, relays, and motors, can be analog or digital.

Central Processing Unit (CPU):

The CPU is in charge of processing data from the I/O modules, executing preprogrammed logic, and controlling output signals to the actuators. The CPU is composed of a microprocessor, memory, and additional support circuitry.

Programming Software:

Programming software is use to create and modify the logic that governs how the PLC system operates.

Centralized:

In a centralized architecture, each I/O module is directly coupled to the CPU.

This design is employed by applications with a constrained number of I/O modules and read Also Industrial Robots: Super-Smart Machines in Factories

Decentralized:

In the distributed architecture, I/O modules are dispersed throughout the system and connected to the CPU through a network. This design is typically used in applications with a large number of I/O modules.

We are Asteam Techno Solutions Pvt Ltd: the go-to company for industrial automation products. Make a contribution to the circular economy and providing all industrial automation products for businesses and factories and also providing service work for them. Provide automation solutions with reputed brands including Allen Bradley, Mitsubishi, Phoenix Contact, Siemens, Schneider, Moxa, VIPA and more. Currently our staff members are serve a growing number of national and international customers each day.